GIZ funds Mobile Cassava Processing Innovation field in Ogun State

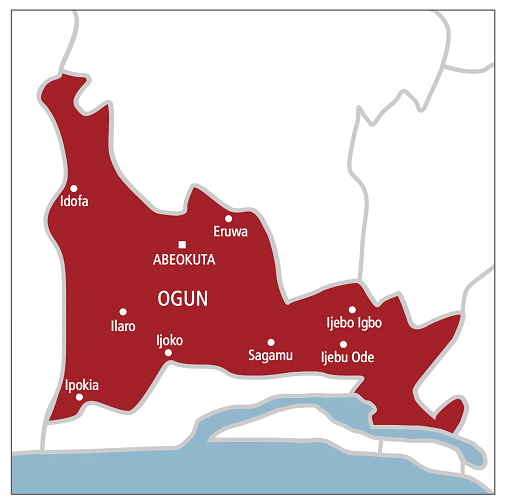

The Green Innovation Center for Agriculture in Africa in partnership with the Federal Institute of Industrial Research Oshodi (FIIRO) has established the funding of Cassava Processing Innovation field in Ogun State.

To achieve these goals, GIZ under it’s Green Innovation Center For Agriculture in partnership with Federal Institute of Industrial Research, Oshodi (FIIRO) and a packaging company, Bosch,

took step to create access to modern technologies called Mobile Cassava Processing Innovation (MOCAPI) for cassava processing into garri with an attractive packaging without the need to invest in expensive processing equipment.

The GIZ Cassava value chain adviser, Mr. Hide Ajibola stated this in Abuja recently saying:

“what we have just done was to ascertain some qualities among the localities because being a field test, we are bound to make a lot of recommendations which will be added in the final product.

We have been to Ponkuku, Ikereku Idan and Ibara, in a process that started since Monday, but the key point was that the women learnt about the need to be hygienic with the use of the MOCAPI and we have also seen that under this innovation, we have lots of socio-economic advantages.

Now the women spent less time and money for their garri processing with more time for their family”.

In his testimony, one of the farmers in the state Mrs. Oluremi Adesoji said it had never been this good as garri processing now look easy, neat and hygienic.

Nigeria is the leading cassava producer globally with over 80% of the production processed into food products and consumed locally, while majority of Nigeria post harvest losses also happened along this line.

It was noted that the major challenge confronting the sector is the large small holder women farmers engaged in both farming and processing mainly at cottage level.

Some have formed cooperatives with hundreds of individuals sharing one site and working together like the Ifesowapo cooperative farmers and other small scale women farmers in Abeokuta North local government of Ogun state.

According to GIZ findings, technology used is basic with hygiene usually not up to standard, even though cooperatives and micro enterprises diversify their production according to market demand, their business skills can be improved.

The Mobile Cassava Processing Innovation (MOCAPI) is a combination of Grater, Hammer mill, Presser, used for the grated cassava tubers, packaging machine and a mobile power generator of about 2.5kg all together in a three-cycle that tows a hydraulic press mounted on a trailer which can be moved to a processing site for the entire dehydration process while milling and packing garri for customers.

The chairperson of Ifesowapo Cooperative Society. Ponkuku, Ishaga-Orile, one of the benefiting cooperatives, Mrs Fatola Oniola, said the members have not been privileged to receive such training or have opportunity to use a mobile machine like the MOCAPI,

but now, the members have learnt the use of scaling, and the need to be hygienic though her members produced well above 200kg of garri per week.

“That is why we are pleading with GIZ and it’s partners to assist us not just with the MOCAPI solution alone, but in other value chains. We quite appreciate this short field test, but we are pleading for more.

It would surprise you that we have 45 women in our group alone with only 3 men, so we need any help we can get.

“We are also pleading with the government to assist us with fund and off takers of our produce. And if we can get the MOCAPI solution, we can package our garri and take them to offices to market.

That is why I am insisting that GIZ should follow up what they have started by empowering us”, she said.

The Bosch project manager, for the MOCAPI project, Mr Jide Obasa, on his part appraising the exercise said, the process for the project commenced in 2017, with the identification of the areas in the value chains where there are lapses, especially in the area of hygiene having visited quite a number of towns and villages in Ogun and Oyo states.

“We came up with the idea of designing a mobile unit that could work from one locality to another to help the small scale women farmers in order to alleviate the processing challenges they are going through so we can make it better.

“We started the design in the first quarters of this year by identifying the right partners to help. FIIRO helped in processing, in the pack, we have the grater, hammer mill, presser and the packaging unit provided by Bosch to help achieve a good packaging,” he explained

The director and head of department, Food Technology, in FIIRO, Dr. Oluwatoyin Oluwole, said FIIRO has worked extensively on developing various processing technology in the area of cassava utilization, and discovered that GIZ too has similar interest.

“In fact, it was GIZ that initially contacted FIIRO, and our meeting ended as a collaborative initiative with the packaging company known as Bosch, this became a tripartite partnership with each organisation’s role defined”.